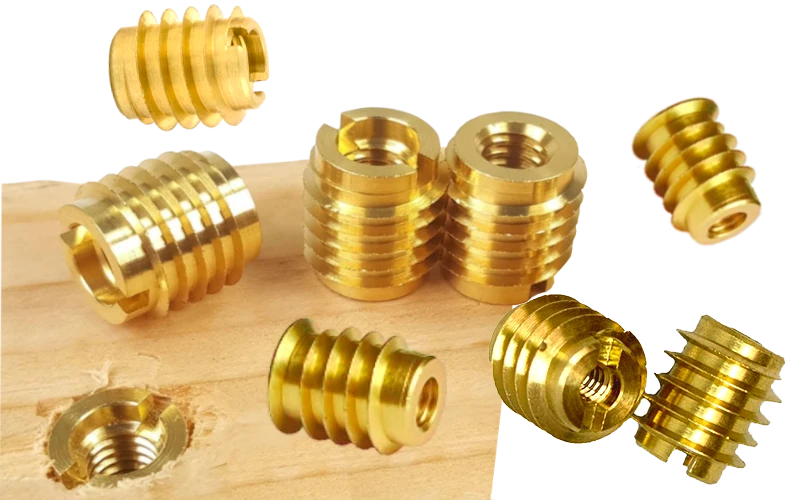

Technically plastic molding inserts are not much different than other types of inserts. Main difference is the process of fixing the insert into the host or the mould. Plastic moulding inserts are over-molded by plastic or resin. In the molding process the insert component is precisely positioned into a mould and then it is over-molded with plastic or resin.

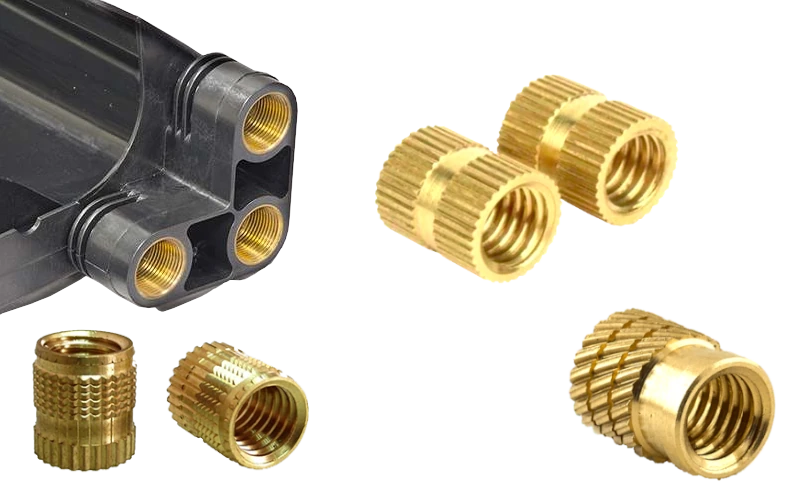

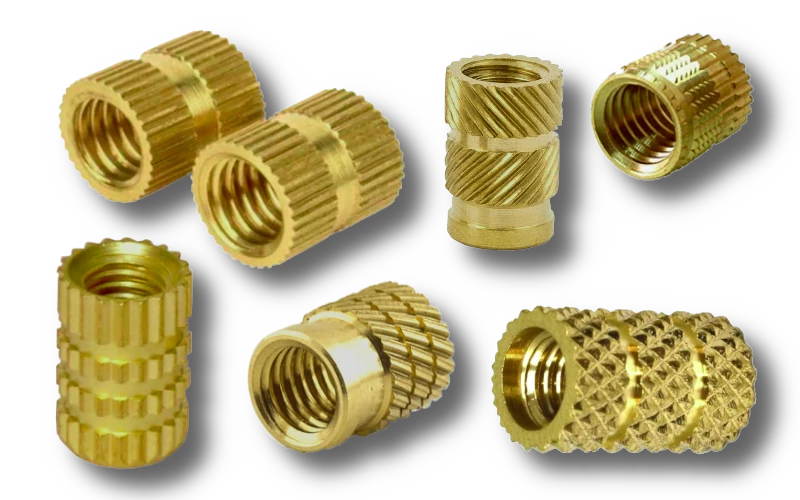

- Brass Molding Inserts

- Over-Molding Brass Inserts

- Embedded Brass Inserts

Know More...